Contract Manufacturing

Top of the line manufacturing

facilities, equipment, and team expertise.

Flory Industries is ready to partner with you.

Flory Contract Manufacturing has been providing full service, custom contract metal fabrication for a variety of industries since 1986. Today the Contract Manufacturing Department has expanded to offer a full, turnkey contract manufacturing solution.

As an established and vertically integrated OEM operating since 1936, Flory is uniquely positioned to strategically partner with companies from a wide range of industries, by offering our services and access to a robust Supply Chain network and cutting-edge Manufacturing facilities and team, from Manufacturing Engineering to Metal Fabrication to Professional Finishing to Assembly and more. We would love to hear about your product or manufacturing bottle neck and discuss how we can help you scale production.

Contact us at contractfab@goflory.com to discuss partnership opportunities.

Manufacturing Facilities

Salida, CA

>139,000 square feet of facilities on 26 acres

Live Oak, CA

>87,000 square feet of facilities on 14 acres

Overview of In-House Manufacturing Services and Capabilities

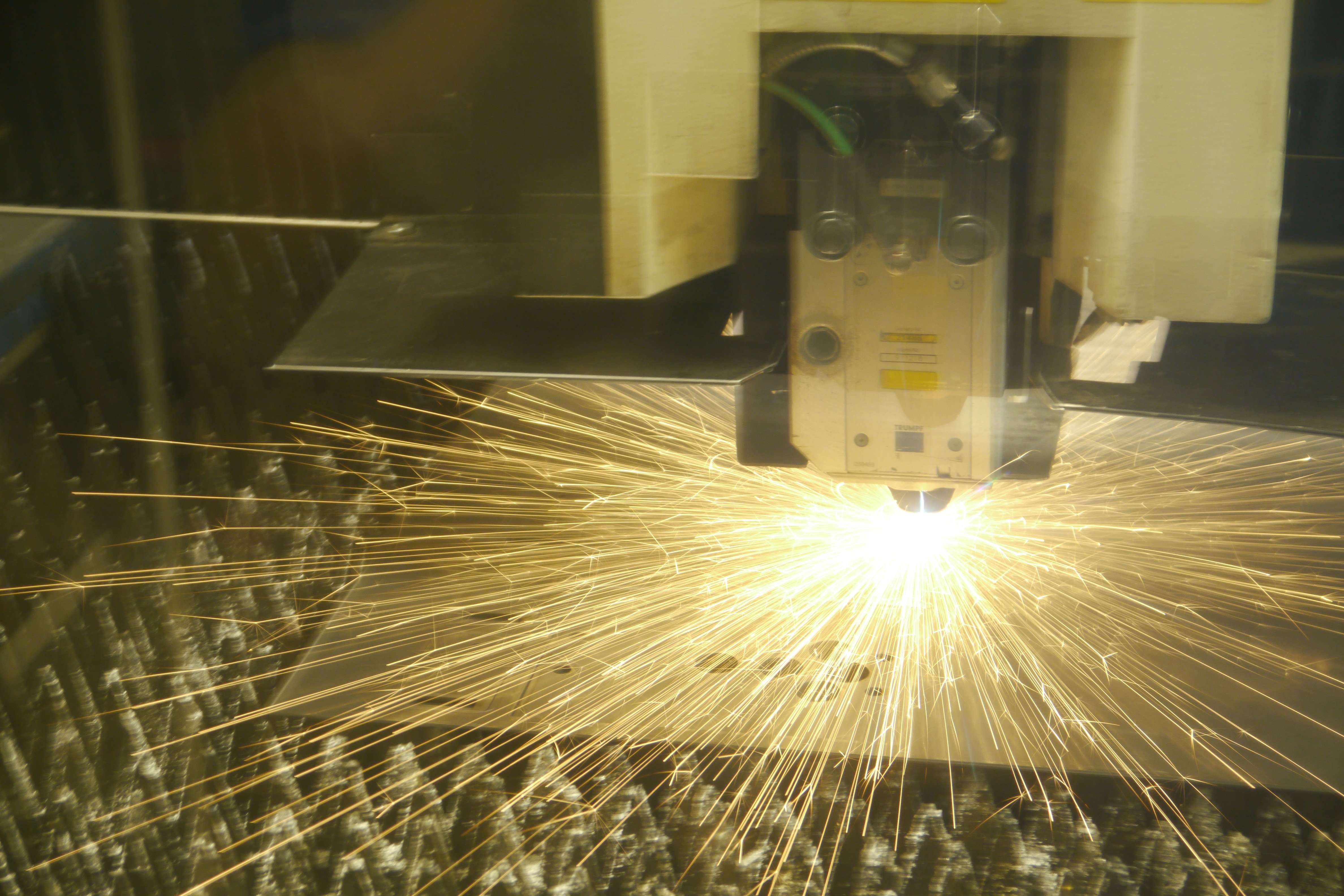

- CNC Laser Cutting - Up to 1” hot roll plate, 78” x 157” work piece capacity, 60” x 120” shuttle table and automated material handling

- CNC Punching - Multi-tool capacity, up to 3/16” mild steel, 19 tons

- NC Punching - Single station punch, 50-ton capacity

- CNC Forming - 144” max. length, automatic tool changer

- Shearing - 3/16” x 120” mild steel capacity

- Machining - 3 axis vertical machine center 50” x 20” x 25” travels, 15” CNC turning center, 20” manual lathe

- Fasteners - 8 ton capacity for press hardware insertion

- Rolling – 5/16” x 6’ CNC roll

- Saw Cutting – Automatic vertical tilt saw, 60 Degree

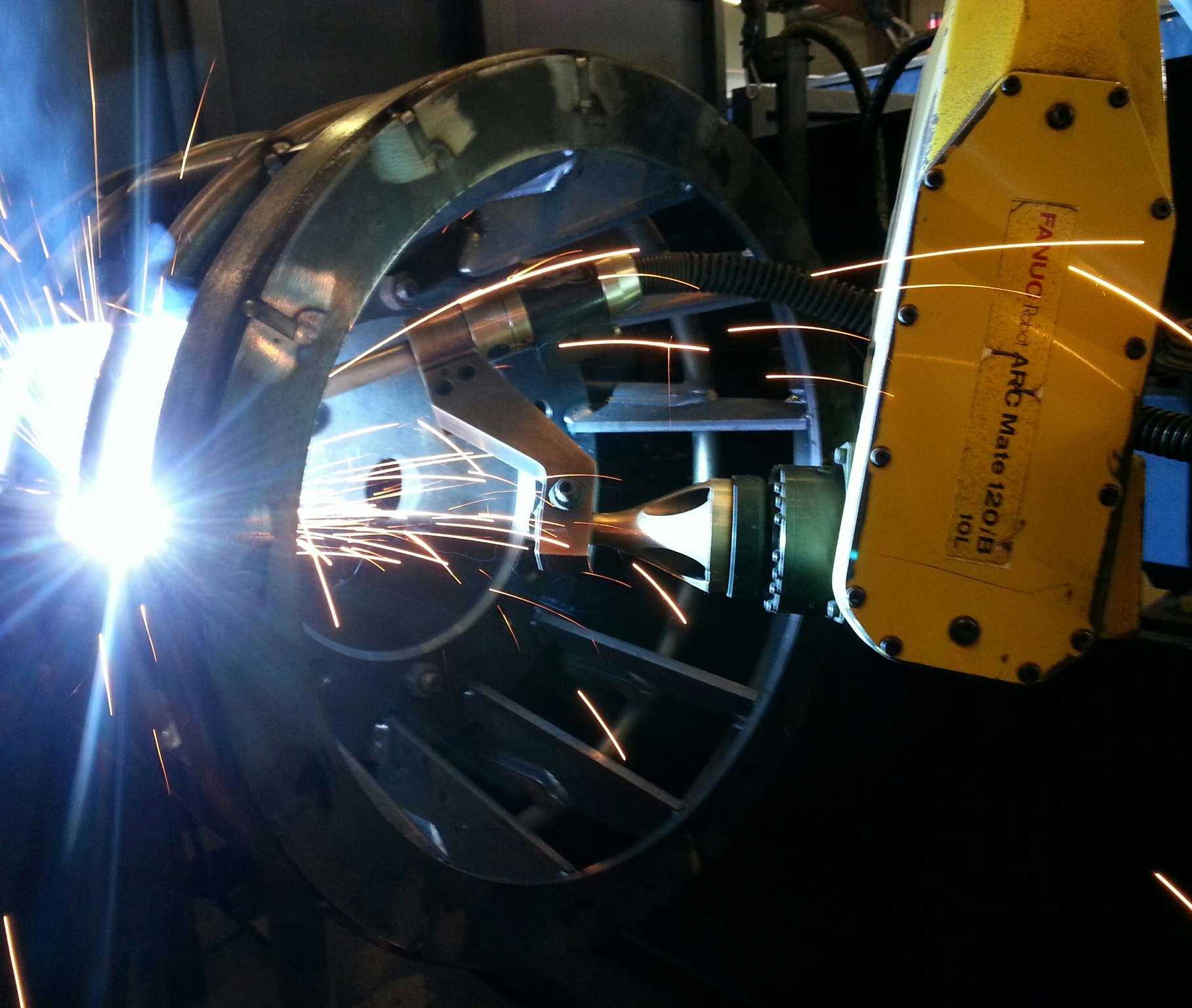

- Welding – Robotic MIG welding, GMAW and GTAW on mild steel, stainless steel, and aluminum

- Professional Finishing – sand blasting, phosphate wash, powder coating and wet paint, 16’x 30’ curing capacity

- Assembly – Skilled technicians in PTO/Hydraulic implement and diesel-powered equipment assembly, machine electrical/control assembly, cab interior detail work, and quality control/test run procedures

Equipment List

- Amada ENSIS3015AJ 9000KW fiber laser

- Amada LC3015F1 6000-watt laser

- Trumpf TruLaser L5030 5000-watt laser

- Mazak Optiplex 4020 fiber laser

- Mazak Optiplex 3015 CO2 laser

- Trumpf TruPunch 1000 CNC punch

- Whitney 50-ton CNC single station punch

- Trumpf TruBend 5130 130-ton press brake

- Amada HG1003 ATC 110-ton press brake

- Trumpf TruBend 3120 130-ton press brake

- Trumpf TrumaBend C66 65-ton press brake

- Trumpf TruBend 3066 65 ton press brake

- Cincinnati CB series 135 ton press brake

- Accurpress 250 ton, 12’ press brake

- Accurpress 175 ton, 12’ press brake

- Amada ¼” x 10 ft. precision shear

- Amada 10 ga. precision notcher

- (2) Haeger 8 ton fastener inserters

- Davi MCA 2017 CNC roll 5/16” X 6’ 16ga. x 12” roll

- Marvel 2125A-PC3-60 automatic saw

- Marvel band saw

- (2) HAAS 4SS vertical machine centers

- HAAS ST-25Y CNC lathe

- HASS ST-45 CNC lathe

- HASS ST-30SS CNC lathe

- Okuma 750MY CNC lathe

- Clausing Colchester 21 120 lathe

- Bridgeport mill

- Clausing 1600H radial drill

- Morrison 1-¼” capacity key seater

- (2) Lincoln Electric System 35 robotic welding dual table cells

- Lincoln Electric 55 robotic welding dual table cell

- 450 amp, dual headstocks

- 66 Total MIG and TIG power sources

- Miller portable spot welder

- Acme 30kva spot welder

- Nelson stud welder

- 16’ x 30’ confined media blast booth

- 4’ x 4’ small media blast cabinet

- 16’ x 30’ powder coat booth

- 16’ x 30’ liquid spray & bake booth

- Manual phosphate wash

- SOLIDWORKS 2023

- Radan nesting /profiling software

- HSM Works CNC lathe & mill

- Octopuz Welding OLP

- Amada press brake OLP

- Trumpf press brake OLP

- DraftSight 2022

English

English